- Home

- Passivation

Chemical Passivation

Chemical Passivation Services in Houston, Texas

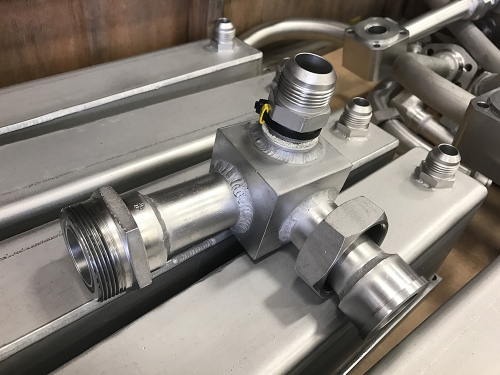

When the correct alloy has been chosen for a specific environment, and it still rusts, then something has likely affected the surface of the material. Passivation is the process in which surface contaminants including rust are removed from metal material and parts to perform as it is engineered. Real-world fabrication, welding and handling of stainless steel components will leave surface contaminants. These contaminates, including weld oxides and embedded particles, hinder stainless steel’s natural ability to resist corrosion. Pickling and/or Passivation can remove these surface contaminants, and allow the material to perform as it is engineered. Common parts and components we passivate include valves, ball valves, tanks, large parts & surfaces, and more.

When to Passivate?

Because real-world fabrication and handling operations degrade the surface properties of the material, all corrosion-resistant alloys benefit from passivation prior to going into service. Passivation may also be performed on a routine preventative maintenance schedule. Some companies schedule routine passivation once a year while others passivate more frequently as a result of frequent high chloride levels.

Passivation Specifications

| Name | Description |

|---|---|

| ASTM A967 | Standard Specification for Chemical Passivation Treatments for Stainless Steel Parts |

| ASTM A380 | Standard Practice for Cleaning, Descaling, and Passivation of Stainless Steel Parts, Equipment, and Systems |

| QQ-P-35C | Federal Specification: Passivation Treatments for Corrosion-Resistant Steel (replaced by ASTM A967) |

| ASTM B912 | Standard Specification for Passivation of Stainless Steel Using Electropolishing |

| ASTM B600 | Standard Guide for Descaling and Cleaning Titanium and Titanium Alloy Surfaces |

| MIL-S-5002 | Surface Treatments and Inorganic Coatings for Metal Surfaces of Weapon Systems |

| SAE AMS 2700E | Passivation of Corrosion Resistant Steels |

Passivation Applications

Harrison is a leader in passivation services for the following industries and applications:

Our facility is located in Houston, TX, but we provide our services globally. Contact us today or: